Industry Applications Applications Across Industries

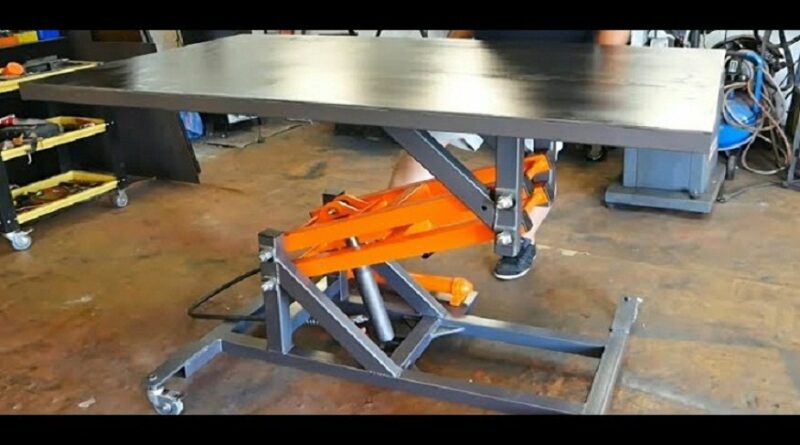

Scissor lift tables are extremely versatile, and used across countless industries, each having their own needs and challenges. In manufacturing, they play an essential role in assembly lines where parts need to be lifted to a predetermined height for mounting or subsequent treatment. Not only speed up the production process but also make the work apparent. In warehouses, these must be used to reach out to get goods from high shelves or to load or unload heavy items, improving operations and minimizing manual lifting.

Although they are often used in industrial applications, scissor lift tables are also frequently used in the construction industry. They help with things like putting in fixtures, maintenance on high structures and access to hard-to-reach places. Negative impact on the human body due to manual processes has prompted automation of labor equipment to function in conjunction with technological treatment process.

Step ladders Step ladders continue to play an important complementary role to lift tables, particularly in locations where a complete lift table is not needed. Proof that step ladders certainly do offer basic height for reaching fairly high locations, but scissor lift tables are always a much sturdier and safer option for taking care of hefty loads, whilst working at taller heights. The complementary nature of these two approaches serves to emphasize the greater need for a suite of tools that address diverse operational considerations.

Enhancing Workplace Safety

Optimal Safety in the Workplace workplace safety is of utmost importance in any sort of industrial environment Answer: One of the major advantages in using scissor lift tables is the addition of a much lesser risk of injury. Manual lifting has been associated with musculoskeletal injuries resulting from repetitive stress and awkward postures. Scissor lift tables enable workers to automate the lifting process, allowing them to attend to other crucial aspects of their work while minimizing fatigue and the risk of accidents.

These tables also incorporate many safety features, providing protection for the operator, as well as the load. Wherever you go in life, there will always be obstacles in your path and a platform that gives way, but you can rest assured that the safety features featured with many models means your platform does not budge at any point, often including built-in safety rails, non-slip tracks, and emergency stop buttons. Then again, the risk of falling when using a step ladders is much greater than a controlled, mechanized lift would pose in any event. This stark contrast highlights why the use of advanced material-handling equipment — such as scissor lift tables — can ultimately create safer work environments overall.

Use of these tables as part of training programs helps with safety as they always represent the same level of accuracy. Generally, operators have to go through in-depth training regarding how to use and maintain the scissor lift tables. Not only does the training enhance operational efficiency as employees understand procedures, but it also fosters a culture of safety and responsibility in the workplace. In most cases, when employers switch from carrying things manually to using lifting tools, they report a substantial fall in workplace injuries.

Cost Effectiveness and ROI

Buying a good scissor lift table is a big investment, but helps your business save a lot of money in a long run. While capital expenditure is usually higher than with conventional lifting solutions, such as step ladders, the return on investment quickly makes the payback justifiable. Operational costs Time means money when it comes to operating a laboratory, and the greater efficiency and safety these tables offer means you spend less money over time. Maintaining production schedules without interruptions can be achieved thanks to reduced downtime, thanks to fewer accidents and less physical strain on employees.

Final thoughts

Notto mention, having more advanced material handling equipment such as step ladders available on site can also bolster worker morale and minimize turnover. Being surrounded by reliable equipment that ensures that employees feel safe and cared for also helps to patch their job satisfaction, and tightens work success and a positive workplace culture. While these less direct benefits may be more challenging to measure, they can have a meaningful influence on the overall effectiveness of an organization.